Almost every single industry that has a production line, is always looking for ways that they can help improve their workflow and operations. With the help of the right engineering firm, you can improve your operations with a bespoke industrial batch oven.

There are several industries that this can apply to, such as aerospace, plastics, electrical, automotive, pharmaceutical and ceramics. The central process is manufacturing, no matter what the industries are creating.

The use of bespoke industrial batch ovens for a range of heat treatments, and thermal processes is always more advantageous than that of other products available on the market.

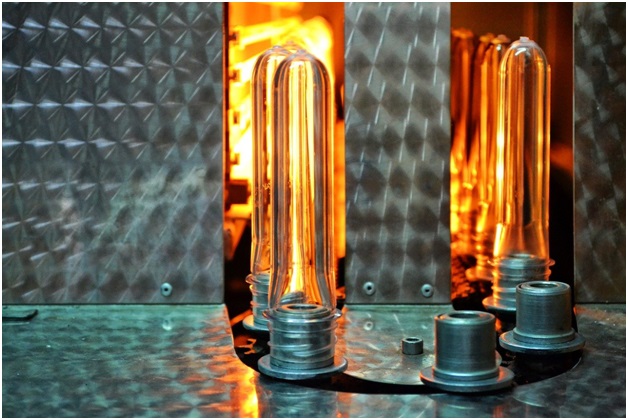

Industrial batch ovens are one of the most common types of industrial ovens. One of the reasons industrial batch ovens are so popular is that they are highly versatile, flexible, and often operate at more than one stage of production, as well as their operator-friendly controls. Industrial batch ovens can be used for various manufacturing processes such as curing, drying, baking, and pre-heating.

In addition, batch ovens are operator-friendly, and they usually have sophisticated features which can easily be generated by a user and, therefore, enable the ovens to meet specific requirements for processes. Moreover, the internal condition of these ovens can be regulated and monitored thanks to their closed systems design. This means you will have more control over the internal environment.

It is important to understand what advantages industrial batch ovens can provide over other oven types before making an informed decision about which to use. For parts requiring very specific environments, or with unusual dimensions, batch ovens are often the best solution.

While you are looking for an engineering firm for yourself to manufacture an industrial batch oven, make sure you think of the below:

Closed Systems

The heating process in industrial batch ovens begins when products are loaded into the closed chamber. In closed systems, there are very few heat exchanges or gas losses, which have a positive impact on the environment. Batch ovens are therefore ideal for applications that require inert air or need to maintain constant, stable environments.

Accommodates Everything

An industrial batch oven can accommodate different shaped products as well. So, if your production line involves odd or large shaped parts of products, it is likely that batch ovens will be the best choice for you. In addition, they are specially designed to handle trays and carts of odd shapes. The versatility of batch ovens can be demonstrated by the range of applications and operations they can be used for throughout manufacturing.

Affordable:

The cost of manufacturing batch ovens is lower than that of continuous ovens. The maintenance requirements are lower as well. Batch ovens, however, can be relatively slow from a production standpoint and incur additional labour costs since they need to be loaded and unloaded manually. Those who provide industrial batch ovens can automate processes and customise their ovens based on their needs to help reduce loading and unloading time.

DRYSYS is one of the best engineering companies across Australia, in the manufacturing of bespoke industrial batch ovens. DRYSYS can design, develop, and construct specialised equipment and machinery for a wide range of industries, including aerospace, automotive, and commercial vehicles, manufacturing, and railroads. The industrial bespoke solutions provided by DRYSYS are known for their quality, innovation, and functionality. DRYSYS’ expertise can help your business, regardless of whether you need bespoke industrial batch ovens or any other air systems.