Enhancing Industrial HVAC Efficiency: Trane CGAF Coil Replacement

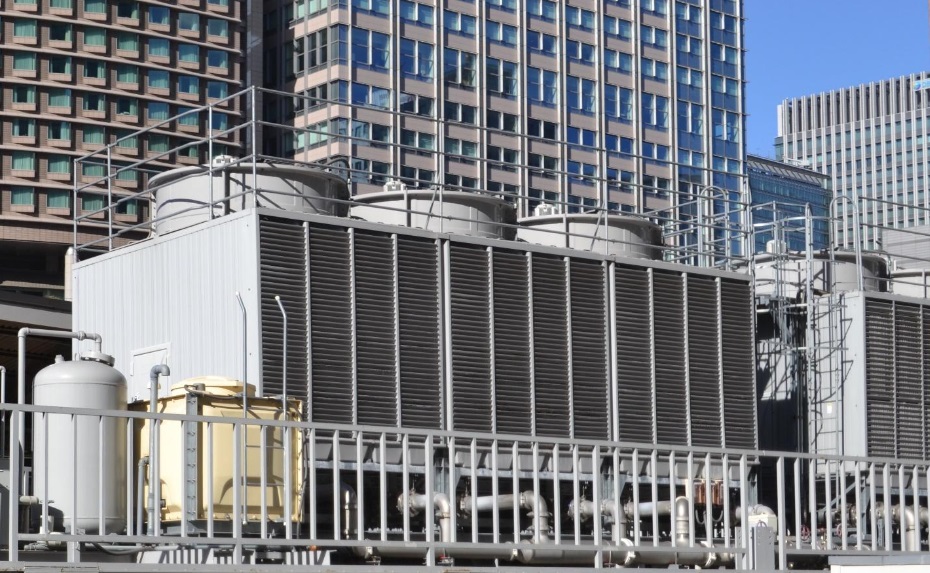

In the realm of industrial equipment, the efficiency and reliability of HVAC systems are vital for seamless operations. A critical component of these systems is the coil, specifically the Trane CGAF coil, designed to optimize heat transfer and enhance overall performance. When these coils show signs of wear or diminished efficiency, Trane CGAF coil replacement becomes a strategic solution. This article explores the importance, benefits, and considerations surrounding Trane CGAF coil replacement, highlighting its role in elevating industrial HVAC efficiency.

Understanding the Role of Trane CGAF Coils in Industrial HVAC Systems

Trane CGAF coils play a crucial role in the refrigeration cycle of HVAC systems, specifically in air-cooled chillers. These coils are integral to the heat exchange process, facilitating the transfer of heat to maintain optimal temperatures within industrial facilities. As with any HVAC component, the need for Trane CGAF coil replacement arises when the existing coils exhibit wear, corrosion, or reduced performance due to prolonged use.

Key Factors Driving the Need for Trane CGAF Coil Replacement:

Wear and Tear in Industrial Environments:

Industrial environments present unique challenges to HVAC equipment, contributing to wear and tear. Trane CGAF coils, although durable, can experience deterioration due to exposure to harsh conditions such as temperature extremes, contaminants, and continuous operation. Replacement becomes necessary to ensure optimal performance.

Corrosion and Degradation:

Corrosion is a common concern in industrial settings, and coils are particularly susceptible. Trane CGAF coil replacement addresses issues related to corrosion and degradation, preserving the integrity of the HVAC system and preventing potential leaks that could lead to system inefficiencies.

Technological Advancements:

HVAC technology evolves rapidly, with manufacturers like Trane consistently introducing innovations to improve efficiency and performance. Trane CGAF coil replacement allows industrial facilities to stay abreast of these technological advancements, ensuring that their cooling systems remain at the forefront of efficiency.

Benefits of Trane CGAF Coil Replacement:

Enhanced Heat Transfer Efficiency:

Trane CGAF coils are designed for superior heat transfer efficiency. By upgrading to these advanced coils, industrial facilities can experience improved heat exchange, leading to enhanced cooling capacity and overall HVAC system performance.

Energy Efficiency:

The design of Trane CGAF coils contributes to energy efficiency. Upgrading to these coils can result in reduced energy consumption, translating to cost savings for industrial facilities over the long term.

Durability and Longevity:

Trane is synonymous with durability. CGAF coil replacement with Trane components ensures a longer lifespan for the HVAC system, reducing the frequency of repairs and minimizing downtime. This durability is particularly important in industrial settings where uninterrupted operations are a priority.

Preservation of System Integrity:

The replacement of CGAF coils helps preserve the overall integrity of the HVAC system. This is essential in preventing issues such as refrigerant leaks, which can compromise the efficiency and effectiveness of the entire cooling system.

The Trane CGAF Coil Replacement Process:

System Assessment:

The process begins with a comprehensive assessment of the existing HVAC system. Trained technicians evaluate the condition of the current CGAF coils, considering factors such as age, wear, and overall performance. This assessment informs the decision to proceed with Trane CGAF coil replacement.

Customized Solutions:

Trane offers a range of CGAF coil options to suit various industrial HVAC applications. The replacement process involves selecting the most suitable Trane CGAF coil based on the specific requirements of the facility. Customization options ensure seamless integration into existing systems.

Professional Installation:

Trane CGAF coil replacement is a precision task that requires professional installation. Technicians remove the existing coils and install the new Trane CGAF coils with precision, ensuring optimal performance and longevity.

Performance Testing:

Post-installation, the HVAC system undergoes rigorous performance testing. This includes evaluating the heat transfer efficiency, refrigerant levels, and overall system functionality. Trane CGAF coil replacement aims not just to replace worn components but to elevate the performance of the entire HVAC system.

Considerations for Industrial Facilities:

System Compatibility:

Industrial facilities should ensure that the chosen Trane CGAF coils are compatible with their existing HVAC systems. Trane offers a variety of options to suit different setups, ensuring seamless integration.

Routine Maintenance:

To maximize the benefits of Trane CGAF coil replacement, routine maintenance is essential. Regular inspections and preventive maintenance help sustain the efficiency and longevity of the HVAC system.

Environmental Impact:

Trane’s commitment to sustainability extends to its products. Industrial facilities considering CGAF coil replacement should factor in the environmental impact of the chosen Trane coils, contributing to a greener and more sustainable operation.

Conclusion: Optimizing Industrial HVAC Efficiency with Trane CGAF Coil Replacement

In conclusion, Trane CGAF coil replacement stands as a strategic investment for industrial facilities seeking to optimize the performance of their HVAC systems. The upgrade is not merely a maintenance task; it’s a proactive step towards ensuring the efficiency, reliability, and longevity of industrial HVAC systems. With a focus on customization, energy efficiency, and durability, Trane CGAF coil replacement is at the forefront of innovations that contribute to elevated thermal management standards in diverse industrial applications. Upgrading to Trane CGAF coils is a testament to a commitment to efficiency, reliability, and the seamless operation of industrial HVAC systems in the ever-evolving landscape of industrial equipment.